Minimizing the Impact of Wastewater

Our NWPX Park division develops, designs, and manufactures wastewater solutions that prevent environmental damage, safeguard public health, and support proper treatment. We offer a range of solutions to monitor, separate, and remove pollutants and contaminants from wastewater before it is released into the environment or a treatment plant. This process typically involves physical, chemical, and biological methods to remove or reduce pollutants such as oil and grease, chemicals, heavy metals, and solids. Additionally, wastewater pretreatment also involves the containment and prevention of hazardous substances from entering the public sewer system.

Read more about these products >

Wastewater Pretreatment

The main purpose of pretreatment is to prevent environmental damage, safeguard public health, and ensure the proper functioning of the wastewater treatment system. NWPX Park creates cost-effective wastewater solutions tailored to many industries and everyday use.

Some of these products include Oil Water Separators, which remove oil from wastewater before discharge into a sewer system; Grease Interceptors, commonly used in commercial restaurants and food manufacturing facilities to prevent FOG (fats, oils, and greases) from disrupting wastewater treatment operations; and Solids Interceptors that collect and contain solid substances in commercial wastewater. All of these systems protect sewer infrastructure, reduce municipal treatment costs, and comply with regulations while minimizing environmental impact.

Reuse and Containment

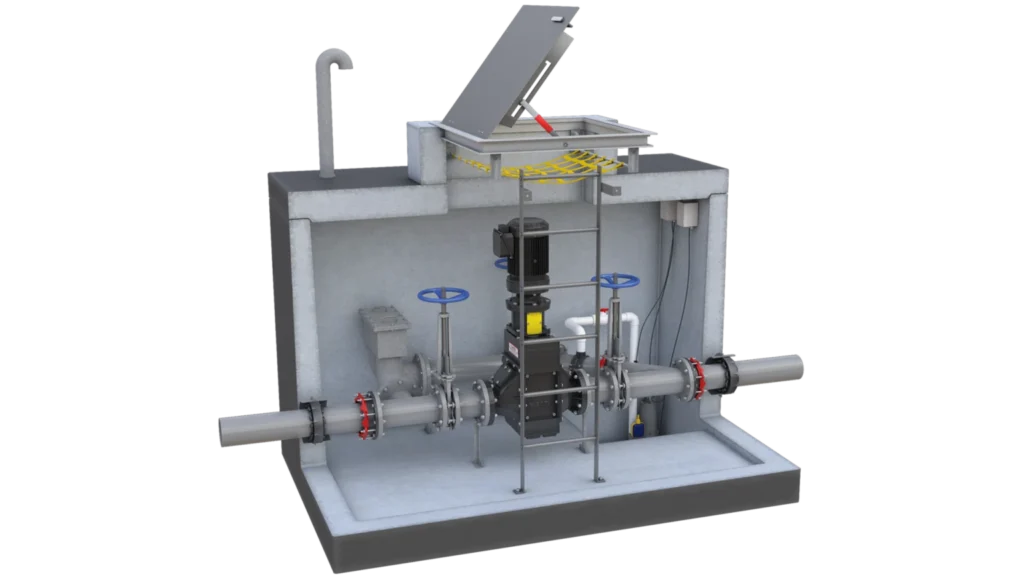

Our wastewater reuse and containment systems are used in commercial and industrial wastewater applications where the wastewater is detained for treatment or periodic removal. Our reuse systems include multiple stages of water clarification to separate sediments and oils from wastewater. Water that cannot be reused is stored in our containment systems, which may be needed due to constituents within the wastewater or availability of wastewater treatment facilities.

Some of these products include our Decontamination Tanks, tanks that intercept and store hazardous wastewater collected from medical, research, military, or industrial facilities; our Car Wash Water Reclaim Systems, underground precast concrete reclaim systems that use a sand-oil separator to collect and filter water for reuse as well as pretreat unusable wastewater before it is discharged to a sewer system; and our Fire Fighting Foam Containment Systems that provide automatic management of aqueous film-forming foam (AFFF) used for fire suppression systems at aviation facilities and fire training facilities. All of these advanced containment products are delivered to the job site pre-packaged and ready to install.

Control and Filtration

Most of our control and filtration systems include automatic features that sense wastewater and trigger action to support the removal of debris or oil before entering the stormwater or sanitary sewer system. These products protect downstream pumps, processing equipment, and sewer lines, and are used in stormwater management systems as well as industrial and municipal applications.

The Fox Valve Runoff and Washdown Diversion System is specially designed to manage water runoff in outdoor wash areas and automatically directs wastewater and stormwater to their respective sewer systems. Our Sewage Grinders prevent costly sewage pump clogs by macerating rags, wipes, diapers, and other disposable items that commonly clog sewage pumps, and are often used at prisons, hospitals, and nursing homes. Our Bar Screen system is placed in the sewer line or wastewater treatment plant, and as the wastewater flows through it, the bars catch and retain the solid materials, allowing the liquid to pass through.

Industrial Dewatering and Separation

Our process products include filtration and separation systems focusing on dewatering containers, mixing and blending equipment, and chemical treatment systems and specifically support the needs of municipal, industrial, and petrochemical projects.

Our Dewatering Containers turn large volumes of liquid waste into small volumes of solid waste, streamlining waste-hauling operations and minimizing disposal costs. This cost-effective way to collect, dewater, transport, and dump sludges, slurries, and wet solids is used in a variety of applications. Dewatering Containers can be fixed or mobile and use either a flocculation and filtration process or disposal media process. The process products also include inline polymer mixing and batch systems as well as large-scale oil water separators.