Sustainability Vision

- Create a safe and engaging workplace environment where employees feel valued and supported in such a manner that enables them to succeed and grow.

- Cultivate a resilient and highly skilled workforce through skill-building, ongoing education, leadership development, and equal opportunities for advancement.

- Prioritize continuous improvement in reducing the Company’s impact on the environment.

Environmental Priorities

- Greenhouse Gas Emissions: Implement energy-efficient technologies in production lines, set science-based targets for GHG emissions reduction.

- Waste Reduction: Leverage existing Lean Manufacturing principles to reduce excess material usage and optimize production processes.

- Water Management: Install water-efficient systems and reuse wastewater where feasible, monitor and reduce water usage in production processes.

Social Priorities

- Employee Health and Safety: Maintain strict workplace safety standards, regularly audit and improve working conditions.

- Human Capital Development: Provide training programs for skill development, advancement opportunities.

- Community Impact: Partner with community organizations for community impact projects.

Governance Priorities

- Responsible Practices: Adopt the best practices to meet the needs and goals of the Company.

- Supplier Code of Conduct: Collaborate with suppliers to improve sustainability practices.

- Cybersecurity and Data Privacy: Strengthen data protection measures to safeguard data, establish protocols for cybersecurity risk management

Focusing on What Matters Most

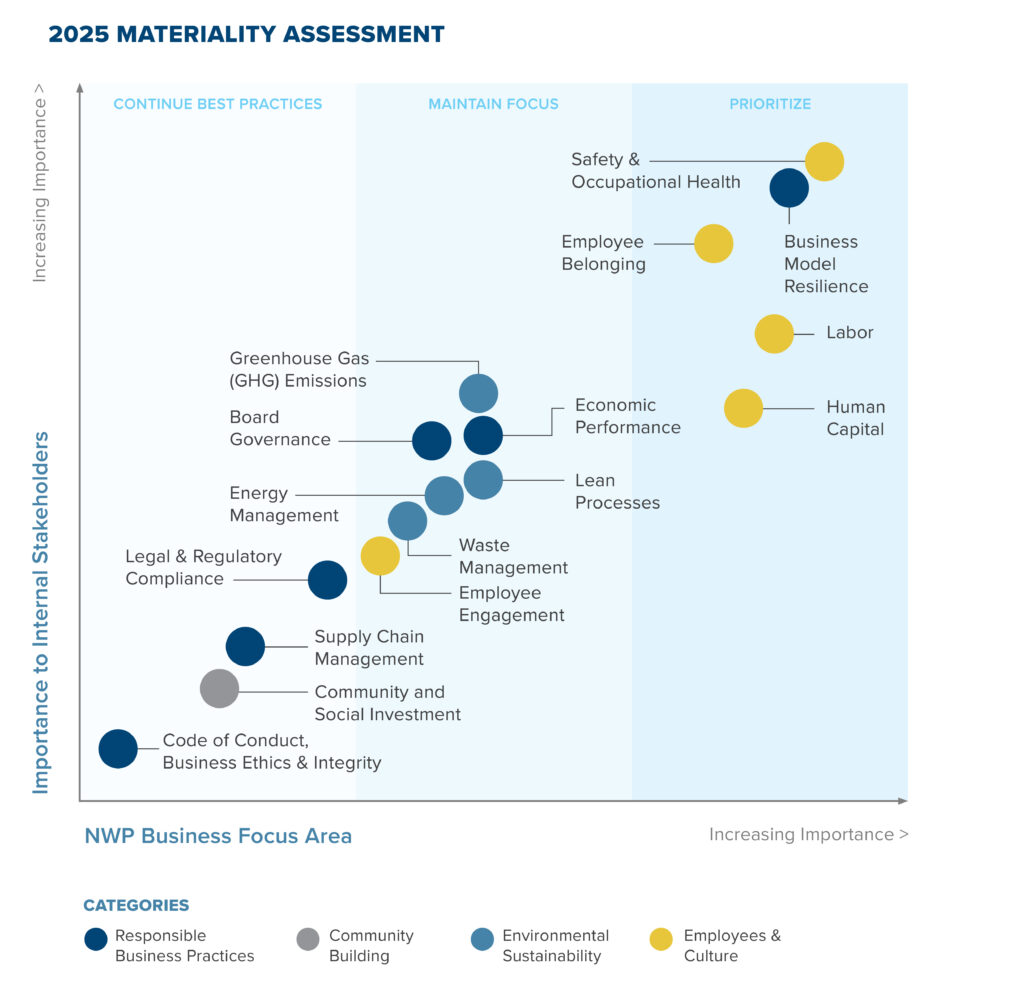

We believe that doing the right thing for our business, our people, and our planet starts with listening. In 2023, we conducted a company-wide materiality assessment to better understand the issues that matter most to our long-term success and to our commitment to Corporate Social Responsibility (CSR).

Through in-depth conversations with employees and stakeholders, we identified 16 critical CSR topics and ranked them based on their importance to our people and their impact on our business future. While every topic matters, the assessment helped us sharpen our focus — directing extra energy and resources toward the areas where we can make the biggest difference.

As illustrated in our Materiality Assessment chart below, we will continue maintaining strong practices across all identified topics. However, those in the “Prioritize” category will receive special attention as we work to strengthen our performance and impact even further.

Importantly, our Materiality Assessment is not a one-time exercise. We will regularly review and update our priorities to ensure we stay aligned with what matters most to our business, our stakeholders, and the future we are working to build.

Area of Focus

Water

As a manufacturer of water-related infrastructure products, we have the privilege of bringing water to communities and improving growth and livability. Water is a precious natural resource, and our products support critical modernization projects that replace or rehabilitate crumbling, aging infrastructure, reducing water loss and saving millions of gallons of water a year.

Energy and Emissions

We invest in improvements that not only make our manufacturing more efficient but also prove to be less harmful to the environment. We invest in production methods that minimize particulate release and emissions, keeping them well below regulatory limits and helping to protect the air, water, and communities around us.

Climate

Understanding our climate-related risks and opportunities is important to our long-term business sustainability and resilience. As extreme weather events become more frequent and wildfires pose growing threats, we recognize the need to proactively protect our people, operations, supply chain, and assets. By anticipating these challenges, we strengthen our ability to adapt, respond, and continue delivering essential infrastructure to the communities that depend on us.

Waste

Our approach to waste management focuses on minimizing waste at the source, maximizing resource recovery, and embracing circular economy principles to reduce environmental impact and create new value from by-products.

Sustainability Starts with Responsibility

NWPX recognizes that our businesses can have an impact on the environment if we don’t operate responsibly. We work hard to mitigate adverse effects on the environment caused by our manufacturing processes and the use of our products through development and implementation of proactive processes, procedures, and management systems designed to minimize our effect on the environment whenever possible.

Every employee has a role to play in our commitment to the environment. We seek methods to control pollutants in stormwater runoff and air emissions, enhance energy efficiency, minimize waste, protect biodiversity and critical habitats, improve water quality and availability at every step of our manufacturing processes.

Ongoing Efforts

- GHG Emissions Inventory – Northwest Pipe is working with a third-party consultant to collect and analyze each plant’s Greenhouse Gas (GHG) emissions. Although this program is still in its early stages, the inventory will serve as a valuable baseline.

- Establish Climate-Related Disclosures – We are committed to developing climate-related disclosures in accordance with the recommendations of the Task Force on Climate-Related Financial Disclosures.

- Capital Improvements – Many of our capital improvement projects focus on improving the quality of the work environment for our team, including projects that simultaneously share a sustainability component, such as improved ventilation systems or particulate release and emission reduction projects.

- Lean – We are dedicated to reducing waste in our operations and employ lean manufacturing practices intended to eliminate waste and optimize processes. Plants share their success with monthly reports distributed throughout the Company.

- Recycled Materials – The most used materials in our manufacturing processes are steel and precast concrete—both are made with highly-recyclable natural resources. We procure and work with tons of recycled materials, produce minimal waste during operations, and recycle any remaining materials.

Water Conservation Case Study

Pure Water San Diego

The Pure Water San Diego project is a phased, multi-year program will provide nearly half of the City of San Diego’s water supply locally by the end of 2035. This project uses proven water purification technology to clean recycled water to produce safe, high-quality drinking water. The Pure Water Program offers a cost-effective investment for San Diego’s water needs and will provide a reliable, sustainable, drought-resistant water supply for the City’s growing communities. To support Phase 1 of the program, NWP is supplying over 21 miles of 30- and 48-inch engineered steel pipeline, which will be used to convey wastewater and purified water across the Pure Water network. Manufactured at our Southern California facility in Adelanto, over 8,080 tons of steel was used to produce more than 111,700 LF of pipe for this phase of the project.

Product: 75,447 LF of 48” and 36,254 LF of 30” Spiralweld Steel Pipe with Cement Mortar Lining and Coating with Polyethylene Tape Wrap

Supplemental Materials

Conflict Minerals Disclosure – Northwest Pipe Company does not purchase or trade in any conflict minerals and verifies all supplies in upstream sourcing.

Reporting Frameworks Guidance